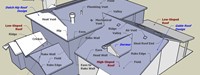

Roofing Guidelines Examples

Our RFP/Guidelines

for Property Owners and/or their Board of Directors will include

some of the example guidelines

listed below. They will be written specifically, and

sometimes in more detail, with some sketches and/or photos

for the replacement/repair of your roof

coverings on the building(s) in your community.

Our Roofing Guidelines are

written to help

both the

Property Owner and

Roofing Contractor

have a good quality roof installation. Passing

our roof inspections greatly reduces

the chance of roof leaks,

other roofing problems, callbacks

and litigations.

Our Roofing Guidelines are written to the same criteria we use when performing our Field Inspections:

RE/COR Inc. performs Mid-Roof Inspections and a Final Roof Inspection to determine if the new roof covering materials and accessories are installed in a workmanship like manner following our RFP/Guidelines and meeting or exceeding the Local City/County Building department's current IBC and IRC Building Codes and their amendments and the 2021 IBC and IRC Building Codes as well as current ICC Evaluation Services Reports (or other ICC approved material testing companies), Roof Covering Manufacturer’s Association Installation Manuals, and Manufacturer’s Installation Specifications/Instructions, and/or other Industry Standards - whichever is more restrictive.

Building Codes and Manufacturer's Installation Specifications/Instructions can sometimes be conflicting and can vary from one area to another. See Building Code Conflicts web page.

Each of our Roofing Guidelines listed below is recognized by one or more City/County Building Departments, however, which roofing guidelines they each recognize varies. Most all recognize at least 80 percent or more and some almost 100 percent of the example guidelines listed here.

Just because your roof is located in one area does not mean it should be roofed to a lower standard, thereby increasing the chance of developing roof leaks, or other roofing problems, callbacks and possible litigation.

Many Roofing Contractors will bid the roof to the local building code only, just to get the job. They fail to let the property owner know of the many other choices there are to greatly reduce the chance of problems occurring. Our Roofing Guidelines provide property owners with information so they can make the decisions, not the Roofing Contractor, on how they want their roof covering installed.

Our Roofing Guidelines are based upon the weather conditions that occur in Colorado that affect and dictate the use of roofing materials and their installation. These weather conditions are known as the Minimum Building Design Criteria or in this case the Minimum Design Criteria for the installation of New Roof Coverings.

Our Minimum Building Design Criteria for the Installation of New Roof Coverings

In the State of Colorado

Local City/County Building Design Criteria for Roofing will be used if more restrictive than what is listed below. Examples might be as you move west and up in elevation the wind speed and the ground snow load criteria increases.

-

100 mph 3-second gust wind speed

-

The Minimum mph 3-second gust wind speed criteria increases the further west toward and into the mountains west of Denver the structure is located. We utilize, which most City/County Building Departments also use, the general guidelines published in the 2006 Colorado Front Range Gust Map document prepared by Jon A. Peterka of Cermak Peterka Peterson, Inc. but starting with the 110 mph 3-second wind gust contour listed on their maps and going west only from there. We and many City/County Building Departments consider the rest of the Metro Denver Area east of the 110 mph contour to be a Minimum of a 100 mph 3-second gust wind speed zone.

-

-

30 pounds per square foot ground/roof snow load

-

The Minimum 30 pounds per square foot ground/roof snow load criteria increases the further west toward and into the mountains west of Denver the structure is located by 5 pounds per square foot for every 500 feet rise in elevation. We generally follow Snow Load Tables similar to the one Douglas County Colorado uses of up to 5999 feet in elevation = 30 lbs./sq. ft. of snow load; 6000 - 6499 feet in elevation = 35 lbs./sq. ft. of snow load; 6500 - 6999 feet in elevation = 40 lbs./sq. ft. of snow load; 7000 - 7499 feet in elevation = 45 lbs./sq. ft. of snow load; 7500 - 7999 feet in elevation = 50 lbs./sq. ft. of snow load; 8000 - 8499 feet in elevation = 55 lbs./sq. ft. of snow load, etc.

-

-

Wind Driven Snow Area

-

All of Colorado, including the Metro Denver Area, frequently receives wind driven snow according to NOAA's National Weather Service issuing everything from Winter Storm Advisories and Warnings to Blowing Snow Advisories every year to Blizzard Warnings in some years.

-

-

Ice Damming at eaves

-

All of Colorado including the Denver Metro Area has Ice forming along the eaves every winter to some extent with as much as 8" to 12" or more of Ice Damming occurring about every 5 to 10 years. Many times this Ice Damming results in damage to the structure and many insurance claims. Both the IRC and IBC have been requiring the use of an Ice and Water Membrane "In areas where there has been a history of ice forming along the eaves causing a backup of water.... an ice barrier shall be installed....". Plus most Roof Covering Manufacturers at least recommend the use of an Ice and Water Membrane, (some require it) not only along the eaves but in valleys and along roof to wall intersections and chimneys.

-

-

3.0 inches per hour for 100-Year, 1-Hour Rainfall (for roof drain sizing)

-

Moderate or Severe Hail Exposure Area

-

We utilize the 2012 IRC Hail Exposure Map Figure R903.5 for all structures whether they are classified as an IRC or an IBC Structure. If the hail stones are large enough to do damage to the roof of a single family house built under the IRC Code, the same hail stones will damage the same type of roof covering on the commercial building built under the IBC Code next door.

-

Examples of Roofing Guidelines

The Roofing Guidelines listed below address only some of the roofing materials and/or circumstances that occur with roofing installations. Failure to follow these Roofing Guidelines or any other requirements not listed here will result in a correction being written in our Roof Inspection Service Report.

Below are some of the more restrictive requirements taken from the Building Codes, Amendments, Specifications, Manuals, and other Industry Standards that are based upon the weather conditions as listed in the above Minimum Design Criteria. These weather conditions do affect and dictate the use of roofing materials and their installation.

Property Owners and/or their Board of Directors should also be informed of the risks involved if they should choose to Opt Out of any roofing guidelines that are not required by their local City/County Building Department. If the Property Owner and/or their Board of Directors does elect to Opt Out of any of the Roofing Guidelines, we will write a Conditional PASS Final Roof Inspection Report. Our Conditional PASS Final Roof Inspection Report will list any items from our Roofing Guidelines that were Opted Out of by the Property Owners and/or their Board of Directors but will contain the words "However this New Roof Covering PASSES our Final Roof Inspection because we understand that the Property Owners and/or their Board of Directors have Opted Out of our Roofing Guidelines and/or Corrections/Observations."

Again, Property Owners may Opt Out of some of our Roofing Guidelines at their own risk that are not required by their Local Building Department. However, if you, the Property Owner and/or their Board of Directors, incur damage as a result of your choice to opt out of any of our Roofing Guidelines remember it is at your own risk, NOT the Roofing Contractor's or RE/COR Inc.'s responsibility to fix it.

We highly recommend that you, the Property Owner and/or the Board of Directors, do not Opt Out of any of the Roofing Guidelines even if one or more are not recognized or enforced by your Local Building Department. City/County Building Departments can and do make mistakes causing litigation between Property Owners and/or their Board of Directors and Contractors.

Examples of Roofing Guidelines that are general to replacing/repairing all Sloped Roof Coverings

- Existing Roof Coverings: Removal of All Roof

Coverings down to the Roof Decking including the Underlayment and existing

roofing nails/staples is required.

- Deteriorated Decking: The decking must be removed

where the decking is water soaked or deteriorated. New or additional roof decking will be required if the

existing decking will not provide a sound, level, and rigid surface.

If the existing roof decking shifts or deflects due to the weight of the

roofing materials, workers, or rain/snow loads, the existing roof decking

must be overlaid or replaced.

Example: Old 3/8 inch decking will need to be overlaid or replaced with new code approved

decking material.

- Underlayment: All underlayments are required to be labeled with the

appropriate ASTM numbers. If using ICC-ES approved "Alternate"

Underlayments they must be applied in the same fashion as the Standard

Underlayment. If 2 plies of Standard

Underlayment are required then 2 plies of the "Alternate" Underlayment is

required.

- Ice and Water Membrane: An Underlayment of an

ASTM D 1970 Ice and Water Membrane (self adhering polymer modified bitumen

sheet) or

equal is required at ALL eaves of sloped roofs applied directly to the

decking and up the roof slope two (2) feet past the interior side of the exterior wall line.

As the elevation of the location of the structure increases so does the

application of the Ice and Water Membrane extend up the roof slope from the

eave. In

the case of a patio cover that has a minimum of three (3) open sides, an Ice

and Water Membrane is only necessary three (3) feet up the roof from the

eave. From Building Codes - "Exception: Detached accessory structures that contain no conditioned

floor area do not require an ice and water membrane."

- The Property Owner and/or Board of directors could Opt Out of this guideline: if not required

by their Local Building Department or the Manufacturer of the roof

covering the Property Owners and/or Board of Directors are using, as long as

the Property Owners and/or Board of Directors understand that there is an increased risk of damage to their structure from moisture getting

into the structure due to Ice Damming that may not be covered by their Property Owner's

Insurance Company. We highly recommend the

use of an Ice and Water Membrane at all Eaves. Valleys, Roof to Wall

Intersections, Chimneys, and Skylights.

- The Property Owner and/or Board of directors could Opt Out of this guideline: if not required

by their Local Building Department or the Manufacturer of the roof

covering the Property Owners and/or Board of Directors are using, as long as

the Property Owners and/or Board of Directors understand that there is an increased risk of damage to their structure from moisture getting

into the structure due to Ice Damming that may not be covered by their Property Owner's

Insurance Company. We highly recommend the

use of an Ice and Water Membrane at all Eaves. Valleys, Roof to Wall

Intersections, Chimneys, and Skylights.

- Metal Drip Edge: A metal drip edge is required at the eaves

for all

roofing materials and at the rake edges with most.

- Fastener Heads: Fasteners shall be flush with the roofing material's

surface, NOT over driven, under driven, and/or crooked for all roofing

materials.

- Fasteners: IRC/IBC approved Corrosion Resistant

Fasteners are required with the installation of all roofing materials and

accessories including battens.

- Weather Exposure: Maximum weather exposure shall not be exceeded.

Check manufacturer's specifications before installation. When a staggered

installation is performed, the coursing of all roofing materials must be

dropped so that the distance between the butt of the lowest roofing material

in one course and the highest butt in the course above does not exceed the

maximum weather exposure allowed.

- Flashing: All rusted, damaged, or

deteriorated roof flashing, vent flashing, metal edging, drain outlets,

collars, and metal counter flashing must be replaced. All galvanized

or pre-painted steel flashings used with all roof coverings must be minimum

26 gauge.

- Exterior Wall Coverings: Siding, Stucco, Brick or

Stone veneer and any other type of exterior wall covering must be kept up

off the roof surface a minimum of 1 1/2" for Steep-Sloped Roofing and 12"

for Low-Sloped Flat Roofing at all rake walls, head walls, parapet walls and

chimneys. Exterior wall coverings of any type cannot be set down on the surface of

the roofing material. Check with the manufacturer of the exterior wall

covering because some, such as James Hardie

http://www.jameshardie.com/d2w/best-practices/quick-start-hz5-us-en.pdf, require their

fiber cement siding to be a minimum of 2" above the surface of the roof in

areas with elevations above 4000 feet.

- Through the Wall (Z Bar) Flashing and Vertical Blocking: (See

our web page

Roof to

Wall Intersections for more information, photos, and drawings.) A

Through the Wall (Z Bar) Flashing and the Vertical

Blocking/Backing piece of lumber are to be used at all Rake Walls, Head

Walls, Parapet Walls, and Chimneys for the termination edge of all exterior

wall coverings.

- If the Though the Wall (Z Bar) Flashing has not been previously

installed: cut the existing exterior wall covering up

off the roof deck far enough to allow for the proper installation of the

new Through the Wall (Z Bar) Flashing to be installed up behind the

existing Water-Resistive Barrier (House Wrap), if there is any, without

damaging the existing Water-Resistive Barrier (House Wrap). Cuts

must be made straight.

- Vertical Blocking/Backing Lumber: is required to be

near the thickness of the exterior wall covering but not thicker. For

example, a nominal 1" x 6" board is actually 3/4" x 5

3/4" and would be

used where the exterior wall covering is 3/4" to at most 1" thick. If

the exterior wall covering is 3" thick then the Vertical

Blocking/Backing Lumber must be a minimum of 2 3/4" but no more than 3"

thick. The Vertical Blocking/Backing Lumber is fastened directly to the

wall studs and set on top of the roof decking with the top of the board

a minimum of 5 1/2" above the surface of the roof decking on Steep

Sloped roof areas for most types of roof Coverings; but a minimum of 6

1/2" for most Clay and Concrete Tile Roof coverings and a minimum of 11" on all Low Sloped/Flat roof areas.

This top edge of the board is what the ledge of the Through the Wall (Z

Bar) Flashing sets on. The Underlayment and Roof to Wall Flashing is placed on

the outside of the Vertical Blocking/Backing Board and behind the

Through the Wall (Z bar) Flashing. The goal here is to move the Roof

Flashing out to the same plane as the exterior wall covering to better drain water off the roof and into the gutters

without having to use large Kickouts at the Eave to Gutter to Rake Wall

Intersections. (See our web page

Roof to

Wall Intersections for more information, photos, and drawings.)

- Though the Wall (Z Bar) Flashing: Install the new

Though the Wall (Z Bar) Flashing extending the upper portion of the

Though the Wall (Z Bar) Flashing up the wall a minimum of 3". The

Water-Resistive Barrier (House Wrap) and exterior wall covering are

placed over this upper portion of the Though the Wall (Z Bar) Flashing.

If there is no existing Water-Resistive Barrier (House Wrap) the upper

portion of the Though the Wall (Z Bar) Flashing is hand sealed to the

wall. The lower portion of the Though the Wall (Z Bar) Flashing is

extended down the face of the Vertical Blocking/Backing Board 3 1/2".

The Though the Wall (Z Bar) Flashing ledge where the exterior wall

covering intersects is normally slightly beveled for better water

drainage and less chance for the edge of the exterior wall covering to soak up any moisture.

The bottom edge of the Though the Wall (Z Bar) Flashing is made with a

1/2" flat hemmed kick. Where the pitch of the roof slope is

less than 3:12 and/or Low sloped Flat Roof Covering Material is used, a

(2) two-piece Reglet Through the Wall (Z Bar) Flashing is used.

- The Property Owners and/or Board of Directors could Opt out of this Guideline and not use

the highly recommended Though the Wall (Z Bar) Flashing if not required

by their City/County Building Department as long as the installation of the

Roof to Wall Flashing can be properly installed. The proper installation of the Roof

to Wall Flashing

without installing the highly recommended Though the Wall (Z Bar)

Flashing would require: 1) the Roof to Wall Flashing must be properly

installed and extended up the wall not only behind the existing exterior

wall covering but behind the existing Water-Resistive Barrier (House

Wrap); 2) not damaging the existing exterior wall covering;

3 )the Roof to Wall Flashing, as in Side Wall Flashing, must be

installed so that it can be easily adjusted with each course of the roof

covering. The above criteria must be met so moisture will be able to drain down the Water-Resistive Barrier

(House Wrap) over the Roof to Wall Flashing and back out onto the

surface of the roof covering as it would if the highly recommended

Though the Wall (Z Bar) Flashing were used.

We highly recommend the use of

Through the Wall (Z Bar) Flashing.

- If the Though the Wall (Z Bar) Flashing has not been previously

installed: cut the existing exterior wall covering up

off the roof deck far enough to allow for the proper installation of the

new Through the Wall (Z Bar) Flashing to be installed up behind the

existing Water-Resistive Barrier (House Wrap), if there is any, without

damaging the existing Water-Resistive Barrier (House Wrap). Cuts

must be made straight.

- Roof Ventilation: Proper ventilation as required

by the IBC and IRC is required for

all roof covering installations for both new roof construction and when replacing an

existing roof covering. Some Asphalt Shingle Manufacturers' Warranties

could be voided if the underside of the roof decking is not properly vented. Check structure for Cathedral Ceilings.

Check for a minimum of 1" gap preferably 2" gap for air flow between the top of the insulation

and the underside of the roof decking. Intake and/or Exhaust Air Vents

may need to be added.

- "Provide net free ventilation area of not less than 1/300th of the

vented space where at least 40% and not more than 50% of the required

ventilating area is vented as Exhaust Vents in the upper portion of the

Attic or rafter space with the balance of the required ventilation of at

least 50% but no more than 60% is provided by eave or soffit vents as

intake Vents." - as is and has been stated in the IBC and IRC.

- "Provide net free ventilation area of not less than 1/300th of the

vented space where at least 40% and not more than 50% of the required

ventilating area is vented as Exhaust Vents in the upper portion of the

Attic or rafter space with the balance of the required ventilation of at

least 50% but no more than 60% is provided by eave or soffit vents as

intake Vents." - as is and has been stated in the IBC and IRC.

- Material Defects: The Roofing Contractor is responsible for culling out all off grade and detectable defects in all roofing materials and accessories.

Examples of Roofing Guidelines for Asphalt Shingles

- Layers of Roofing: The maximum number of layers of roofing is one (1)

with Asphalt Shingles in Moderate or Severe Hail Prone Areas such as

Colorado. When one (1) or more layers of roofing exist, all layers of

roofing including the Underlayment and roofing nails/staples must be removed prior to the installation of a new roof.

- Existing Decking: New decking overlay is

required for asphalt shingles if old existing decking is made of lumber

which is larger than nominal 1" x 6" pieces of lumber or if the gaps between the

boards are more than 1/8".

- Minimum Slope: The minimum slope is 4:12 for standard

single ply underlayment installation. For slopes above 2:12 and less than

4:12 an underlayment of two (2) plies (lapped 19") of ASTM D 226 or D

4869 Type I or II underlayment (commonly referred to as 15# or 30# base felt).

Other ICC-ES approved "Alternate" Underlayments may be used as long as they

are also applied in the same two ply fashion.

- Side Wall Step Flashing: Side Wall Step Flashing must be

properly laced with each and every course of shingles.

- Metal Drip Edge: A metal drip edge is required at both rake edges and

eaves with Asphalt Shingles.

- Number of Fasteners: A Minimum of six (6) fasteners are required for all

strip type shingles. (Some shingles require 8 nails for high wind areas.

See manufacturer's specifications.)

- Location of Fasteners: Corrosion resistant fasteners shall be located

per manufacturer's instructions and not placed in factory applied adhesive.

Nails must also penetrate both parts of a laminated shingle. Check

manufacturer's specifications and association manuals for the correct

placement of nails across the length of the shingle.

- Fasteners: The fasteners for asphalt shingles

must be driven straight and flush with the surface of the shingles; NOT

Under Driven, Over Driven, and/or Driven Crooked. Fasteners that have been over driven require

the hand sealing of the over driven fastener head and adding a new properly

placed and driven fastener.

- Mansard Roof Shingle Fastening: Mansard roof

applications also require the butts of all asphalt shingles to be hand

sealed down in addition to six nails for each shingle per the Asphalt Manufacturer's Association Manual.

Examples of Roofing Guidelines for Cedar Shakes and Cedar Shingles

- Solid Decking: Is required for Cedar Shakes in Wind Driven Snow Areas.

- Minimum Slope: Minimum slope is 4:12 for cedar shakes and 3:12 for

cedar shingles with reduced coursing. For shake roof coverings over

non-living areas with slopes above 3:12 and less than 4:12, an underlayment

of an ice and water membrane is acceptable by many in the roofing industry

including us and some Building Departments for re-roofing only, but not new

construction.

- Underlayment: The required Underlayment is a single

ply ASTM D 226 Type II underlayment (commonly referred to as 30# base felt).

Other ICC-ES approved "Alternate" Underlayments may be used.

- Interlayment: An 18" ASTM D 226 Type II interlayment

(commonly referred to as 18" 30# lace felt) is required to be laced in

between each course of shakes.

- Side Wall Step Flashing: Side Wall Step Flashing must be

properly laced with each and every course of Shakes or Shingles.

- Metal Drip Edge: A metal drip edge is required at both rake edges and

eaves with Cedar Shakes and Shingles.

- Shake Placement: Correct placement of the shakes or shingles is

critical. The maximum gap between the sides for each shake is 5/8". The

maximum gap between the sides for each shingle is 3/8"¯. The sides of each

shake or shingles should never touch. The minimum side lap is 1 1/2" between

joints in adjacent courses for all cedar shakes and shingles.

- Location of Fasteners: Corrosion resistant nails shall be

placed to the manufacturer's specifications and industry standards, not too

high or too low or too far from the sides of the cedar shake or shingle.

See Cedar Shake & Shingle Bureau's

www.cedarbureau.org specifications.

- Fasteners: The fasteners for cedar shakes and shingles must be driven straight and flush with the surface of the shakes/shingles; NOT Under Driven, Over Driven, and/or Driven Crooked.

Examples of Roofing Guidelines for Clay and Concrete Tile

- Minimum Slope: Minimum slope is 3:12 for standard installation of most

concrete and clay tile. For slopes 2 ½":12 to 3:12 an approved flat roofing

membrane is required. The tile and battens are then attached without

fasteners penetrating the flat roofing membrane. However, the minimum slope

is only 5:12 for some clay tile. Always, check with the manufacturer for

low-slope application specifications.

- Underlayment: An underlayment of two (2) plies

(lapped 19") of

ASTM D 226 Type II underlayment (commonly referred to as 30# base felt) is

required. Other ICC-ES approved "Alternate" Underlayments may be

used as long as they are also applied in the same two ply fashion. A single

ply of ASTM D 6380 or D 3909 Class M mineral surfaced rolled roofing

(commonly referred to as 90 pound granulated rolled roofing) may also be used as an

alternative underlayment. An Ice and Water Membrane that complies with

and is labeled ASTM D 1970 applied in single ply fashion may also be used as

the underlayment.

- Vertical Battens: Vertical battens or risers of a minimum 3/8"

thickness and made of cedar or decay resistant treated wood or other decay

resistant materials are required under the horizontal battens and over the

underlayment. (vertical battens are sometimes referred to as

wood lath which is generally 1 1/2" wide and 4' long) The spacing

depends on the size of the horizontal battens based on the total roof loads

for deflection. (See manufacturer's specifications.)

- Horizontal Battens: When using nominal dimensional lumber for

horizontal battens such as 1 x 2s, 1 x 4s, 1 x 6s, etc. the minimum

dimensions are ¾" x 1 ½", ¾" x 3 ½", ¾" x 5 ½" respectively. It is

acceptable to

use lumber that is slightly shy of the minimum dimensions as long as the

distance between the vertical battens is narrowed appropriately.

- Batten Fasteners: Corrosion resistant staples with 7/16" crown may be

used to fasten down the horizontal battens if the vertical battens or risers

are on a maximum of 12" centers. Greater spacing of the vertical battens or risers

requires 8d common corrosion resistant nails.

- Field Tile Fasteners: Corrosion resistant roofing nails

with minimum 5/16" heads or #8 screws are required for fastening of field tile.

Approved fasteners

shall penetrate through the horizontal battens but NOT penetrate the

underlayment.

- Field Tile Fastening: Each and every Field Tile is required to be

fastened down with two fasteners if roof is located in snow and/or high wind

areas.

- Hurricane Clips: Hurricane clips are required for each tile at all

eaves placed near their butts.

- Secondary Flashing: A Secondary Flashing is required

to be roofed into/over the underlayment at all Plumbing, Heat, and

Mechanical Vents, Rake (Side ) Walls, Head Walls, Chimneys, Skylights, Swamp

Coolers, Curbs, Ridge Vents, and any Other Protrusion through the tile roof.

- Primary Flashing and/or Weather Blocking Material: A

Primary Flashing and/or in some cases other approved UV resistant and corrosion resistant

materials must be installed over the Field Tile to keep moisture on their

surface of the Field Tile as much as possible. This Primary Flashing and/or Weather Blocking

Material is required at all Plumbing, Heat,

Mechanical Vents, and along all Rake Walls, Head Walls, Chimneys, Skylights,

Swamp Coolers, Curbs, any Other Protrusion through the tile roof or objects

setting on the roof and under the Hip & Ridge Trim Tile but over the Field

Tile. This Primary Flashing and/or Weather Blocking Material must be

installed fully down on the surface of the Field Tile so that wind driven

snow or rain cannot get up under it and under the Field Tile.

- From the 1997 Concrete and Clay Tile Roof

Design Criteria Manual for Cold and Snow Regions: "Flashing for

tile roofs must do more then just keep water out of the building; it

must also keep water out from under the tile." "The tile surface

shall be flashed to prevent water from getting below the tile.

This is critical in snow areas since the tile can be lifted by the

collection of ice below the tile."

- From the 2015 Concrete and Clay Roof Tile Installation Manual for Moderate Climate Regions, "Openings at the Hips, Ridges, and Head Walls including Chimneys, Skylights, Solar Panels, and Down Slope Horizontal Abutments shall be fitted with weather blocking material to keep water on the surface of the Field Tile." "Step Flashing is typically used in areas where debris can accumulate".

- From the 1997 Concrete and Clay Tile Roof

Design Criteria Manual for Cold and Snow Regions: "Flashing for

tile roofs must do more then just keep water out of the building; it

must also keep water out from under the tile." "The tile surface

shall be flashed to prevent water from getting below the tile.

This is critical in snow areas since the tile can be lifted by the

collection of ice below the tile."

Examples of Roofing Guidelines General for all Flat Roofing Membranes

- Layers of Roofing: The removal of All existing Roof Coverings is

required where there exists (2) two or more layers of any type of Roof

Coverings. (1) One overlay over (1) one existing layer of an approved flat

roofing membrane is permitted by Building Codes provided the existing Roof Covering's surface

has been properly prepared to the manufacturer's specifications.

We highly recommend the removal of ALL existing roof

covering materials down to the roof decking.

- Minimum Slope: New construction shall have a minimum

¼" slope and

Positive Roof Drainage (no standing water after 48 hours). Re-roofing of an

existing structure must also have Positive Roof Drainage (no standing water

after 48 hours). Sometimes extra drains/scuppers and/or crickets will

need to be added.

- Drains / Scuppers: Secondary or overflow drains/scuppers are required

2" above the primary drains on all roofs having walls/parapet walls and shall discharge above grade and be

independent of primary drains/scuppers.

- Ballasted Roofs: Ballasted roofing membranes must follow the criteria set forth in the IBC and ANSI / SPRI RP-4 for the amount of ballast used in the field, at perimeters, and at corners, etc. depending on the height of the building and its parapet walls and if building is in an A, B, C Exposure. Depending on Exposure and Height of structure, a ballasted roof system may be prohibited. (See Section 1504.8 of the 2021 IBC.) We highly recommend not using a Ballasted roof system but install a fully adhered roof system.

The Roofing Guidelines above may change in the future as Building Codes, Evaluation Service Reports, Manufacturer Specifications or Manuals evolve. Also, the above Roofing Guidelines may change if there is some other new roofing material and/or circumstance that occurs with roofing installations that we become aware of or an existing one rises to the degree of being a major problem.

End of Roofing Guidelines Examples.

Visit our

Roof Inspection Services

web page

and the many other web

pages throughout this website to find

answers to your roofing questions and

solutions to your roofing problems.

Page Revised/Updated 2/27/2023